In the oil and gas industries, harmful waste such as radium and unwanted dust is typically produced. Therefore, wastewater is produced from obtaining oil and gas to help reduce the dust from staying airborne or getting kick up on unpaved surfaces. Wastewater, however, from oil and gas wells can sometimes be seen being spread onto unpaved roads to control the high levels of carcinogenic elements in such harmful waste. For that reason, toxic components are likely to be found absorbed by the surrounding soils and water. Manufacturing companies that supply customized equipment for the oil & gas industry can involve numerous high production activities, such as cutting, welding, melting, and more. These processes can cause harmful fumes and dust to accumulate within the manufacturing plant.

About the Oil and Gas Industries?

Oil & gas activities involve the exploration, extraction, storage, refinement, and distribution of oil and gas worldwide. At every stage, the oil & gas industry depends on specialized equipment to retrieve these elements from the earth.

Here are a few products that oil & gas manufacturing companies encompass:

Distribution pipelines

Storage tanks

Pressure vessels

Barges and Tankers

Drilling rigs and platforms

Offshore equipment

Oil & gas transmission pipelines

Infrastructure for refining facilities

Why Should You Use Dust Collectors in Oil & Gas Manufacturing Facilities?

Oil & gas manufacturers often produce equipment for the oil & gas industry and can face several challenges when it comes to indoor air quality and ensuring a safe working environment.

Here are some factors that can contribute to harmful airborne waste:

Toxic Dust: In manufacturing facilities, cutting, and grinding of heavy steel to produce specialized equipment can result in high volumes of dust. Toxic dust when inhaled or ingested can be potentially damaging to the health of workers as well as other equipment and processes.

Large compounds: Companies that produce infrastructure components and equipment for the oil & gas industry are typically large. Due to the required usage of overhead cranes and supporting machinery, effective air quality control methods can be challenging.

Corrosion: One of the most overlook factors that contribute to harmful waste is a highly corrosive environment. As equipment for oil & gas is often left in the area for a prolonged period, corrosion resistance applications are typically used. These coatings often contain highly toxic elements that are usually released into the air, making the environment even more dangerous to work in.

As heavy dust can be a challenge to contain, industrial dust collectors or vacuums are recommended to be used on such sites.

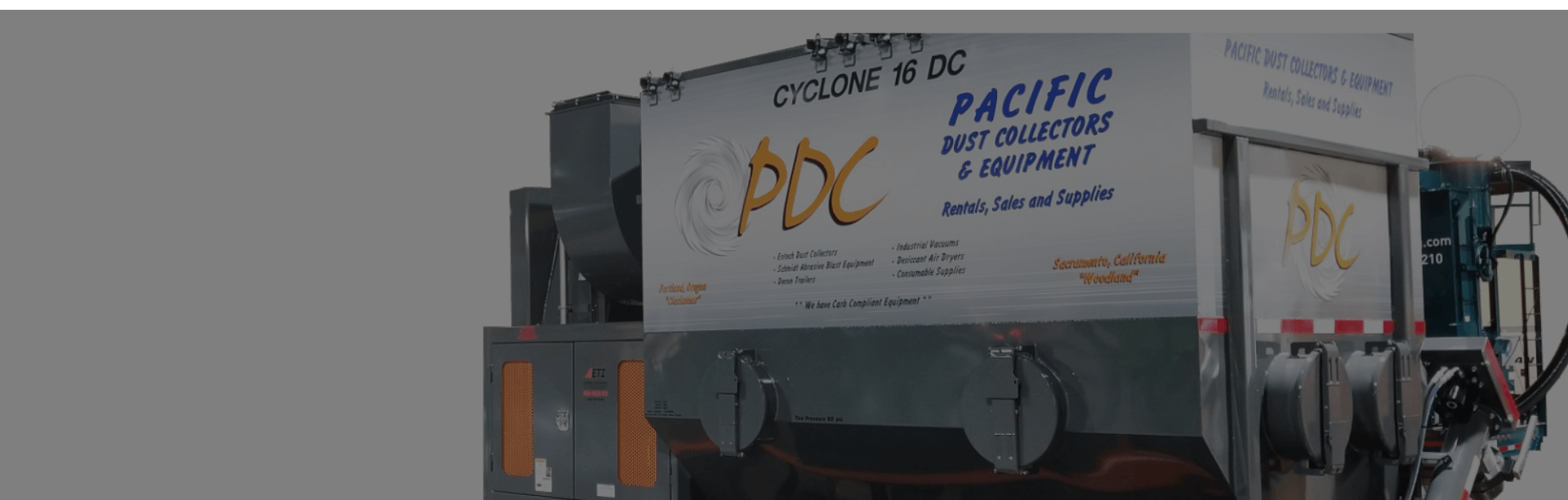

Choose Pacific Dust Collectors & Equipment for Oil & Gas Solutions

Manufacturers working in the oil & gas industry must maintain a safe and healthy working environment for employees as required by the OSHA. To meet those standards, Pacific Dust Collectors & Equipment is here to provide manufacturers in the oil & gas field with a wide range of industrial vacuums and dust collectors that can collect all kinds of hazardous dust and airborne toxic. Our efficient waste collectors can produce powerful and reliable results, ensuring the safety of your workers, the public’s health, and the environment.

If you require assistance with choosing the right products for Oil & Gas, do not hesitate to contact us.